I bought a Rollei 35 TE recently that had a couple of issues and it was driving me bonkers that I could find very little information online about this great camera. Everything I could find, including the service manual, was for the previous generation 35, S and T series cameras.

The issues with my TE were in the meter and lens barrel. The lens barrel was loose and when retracted the lens kept flopping out. (This is common ailment with all Rollei 35 cameras.) The other problem was that the meter would not auto-off after 10 seconds as stated in the manual. It was always on as long as there was a battery in the chamber.

Metering was spot on and agreed perfectly with my Gossen Lunasix3 and the camera still took a great picture despite these issues but they were quickly becoming a major annoyance. Since all the repair estimates I got were for much more than what the camera cost me (and often more that what I could realistically sell it on eBay for) and did not guarantee the meter could be repaired or replaced (in fact most were convinced it could not) I decided to try to fix it myself and document the process for others that might be facing the same issues.

For those doing a repair and in need of extra detail, you can see the full size versions of all the photos in this post by following this link.

Disassembly / ReassemblyI started with the film advance crank removal as this is usually where I have the most difficulty. In this case the crank cover scew came off without too much force. Underneath it is a small copper washer and the crank itself held in place by three screws as seen in the photo here. Next there are 2 philips-head screws on either side of the camera and the rest is on the back: the battery lever cap, another flat-topped screw in the middle of the camera and the rewind lever. The rewind lever has a collar underneath the tab as seen in the 2nd photo. At this point the top cover is not yet ready to be removed as it will not come off without first removing the rewind pin which is held in place by a spring. If you look closely at the rewind pin, you will notice that it has a flat side at half-way between the up and down positions. The pin needs to be turned half-way so the flat side is against the spring so it can be pulled straight out. Use a very small pliers and you may need to use the tip of an x-acto blade to push spring out of the way. Only once pin is removed can the top cover can be pulled off without damage. In the 3rd photo the top cover has been removed and you can see the rewind pin, the retaining spring and the position the pin needs to be in for removal. When reassembling the camera, there is trick to getting the pin back in place properly. The rewind pin pushes up a metal rod inside the camera (seen in the final photo) that unlocks the film sprocket (the toothed wheel that the 35mm holes fit in to directly below it) allowing the film to be rewound. Use small screwdriver to push inner rod up and it will lock in place. This is the only way the rewind pin will fit in back in. The rod will pop back down when you rotate the film sprocket by hand. Try this a couple of times before attempting to put the top cover on. Again, you may need to use the tip of an x-acto bade to push the spring out of the way when reassembling. Once completed, replace the rewind collar and lever, screw it in place and test it out before finishing reassembly. | |

|

|

|

Here are a few more detail photos of the camera without the top cover: |

| |

| |

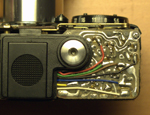

Repairs – Meter Does Not Turn OffThis was what led me to do this surgery on the camera in the first place as I found it a real pain having to pop-in, pop-out the battery all the time. A quick test roll showed that the metering was great (I had already checked it against my Gossen Lunasix3) and it could take a great pic, but the auto-off issue was keeping from using the camera effectively. As soon as I pulled the top cover off I noticed some dry, white powdery gunk under the white wire on the circuit board as seen in the photo here. I scraped it off the circuit board between solder joints with tip of small flat-head screwdriver and happily (amazingly!) the meter immediately started functioning as it should with auto-off after 10 seconds. I figure this was corrosion of some sort that was causing a short and preventing the meter from turning off. | |

Repairs – Loose Lens Barrel This was the only issue that I could find any information about online as apparently affects a lot of Rollei 35’s. Unfortunately, the fix requires breaking down the camera even further to replace a friction collar inside the camera body and I really didn’t want to go to those lengths as all those mechanical bits looked like a little more than I knew how to deal with. Instead I had the idea of going in through the front of the camera between the lens barrel and the collar that holds it in place. Whatever I used needed to be adhesive on one side so it could stick to the inside of the lens collar and stay in place. I tried some flocking paper left over from another project but it was way too thick and after a little experimenting discovered that a simple yellow Post-It was the perfect solution — it was just the right thickness and the adhesive was not too so strong as to make it difficult to work with. I cut off the the adhesive strip from a fresh Post-It and trimmed it so it was about 1.5cm wide. With the camera fully assembled and the lens locked in place, I slid the Post-It between the lens barrel and collar with adhesive side outward against the lens collar and worked it into the camera af far as it would go. This should only be about 2-4mm. I found the best place on my Rollei was at about the 2 o’clock position of the lens barrel. Once the Post-It was in postion, I folded it down against the body of the camera, unlocked the lens and slid it in and out to test if the friction was enough to hold the lens and if the paper would stay in place. Once I was satisfied with the positioning, I used an x-acto knife to trim off the excess paper and then a black sharpie to paint over yellow Post-It color. This method worked perfectly for me producing exactly the right friction to hold the lens and is still in place showing no signs of causing any other issues. Also, once touched up with a black sharpie, you can’t see it unless you really look… | |

|

Easy Battery Solution The best, cheapest battery tip I have found for the Rollei 35 TE and SE cameras came from this flickr discussion [Thank you nadameansnothing!]: http://www.flickr.com/groups/rollei35/discuss/72157622459831809/ Basically, the idea is to use three LR44 batteries and one LR43 battery wrapped in electrical tape to hold them together. With the thinner LR43 in the set the length is perfect and you can wrap enough tape around them to increase the diameter until you get a snug fit in the holder. (I didn’t bother and it works fine.) Best of all, these batteries are easy to find, comparatively cheap and they last forever. All together they produce 6V but the TE / SE meters don’t seem to mind the slight over-voltage as much as the previous generation meters did. So it’s not strictly necessary, but you can use a single depleted cell in the set to get closer to the camera’s native 5.6V. I haven’t really noticed a difference either way. | |

|